Airgroup Dynamics Inc.

Mechanical Engineer

About Airgroup Dynamics Inc.

Airgroup Dynamics Inc. is an FAA-certified 145 Repair Station based in Orlando, Florida, specializing in aircraft component repair and tooling solutions for commercial aviation. Established in 2004, the company maintains over 3,000 repair capabilities and 12 international certifications, serving clients worldwide.

As Mechanical Engineer, I oversaw custom tooling development, established rapid prototyping workflows, and ensured full compliance with FAA standards"–strengthening the link between design, production, and quality assurance across the organization.

Custom Tooling Design & Innovation

I engineered specialized tools that modernized aircraft assembly and disassembly processes, integrating ergonomic design and manufacturing precision to improve technician efficiency.

- Designed over 50 technical drawings and production tools aligned with ASME Y14.5 GD&T standards.

- Collaborated directly with technicians to identify workflow bottlenecks and translate needs into mechanical solutions.

- Reduced assembly process time by 20% through optimized tool geometry and function-driven redesigns.

- Supported end-to-end implementation"–from CAD modeling to validation and shop-floor integration.

Prototyping Pipeline & Manufacturing

Established and managed the company's 3D printing department, revolutionizing our prototyping capabilities.

- Built 3D printing department from ground up, selecting equipment and establishing workflows

- Enhanced prototyping productivity by 30% through additive manufacturing techniques

- Performed precision machining operations including turning, CNC, and milling

- Developed testing protocols to validate prototype performance before production runs

Quality Assurance & FAA Compliance

Coordinated with the Quality Department to validate engineering deliverables against FAA and industry requirements, emphasizing meticulous documentation, traceability, and technical precision.

- Conducted quality assurance assessments ensuring compliance with FAA standards

- Regularly updated and audited over 3,000 capability folders

- Developed diagnostic procedures for component evaluation

- Identified tooling gaps through systematic capability reviews

Components & Assemblies

A comprehensive showcase of precision-engineered components, custom tooling, and aerospace-grade assemblies designed and manufactured at Airgroup Dynamics.

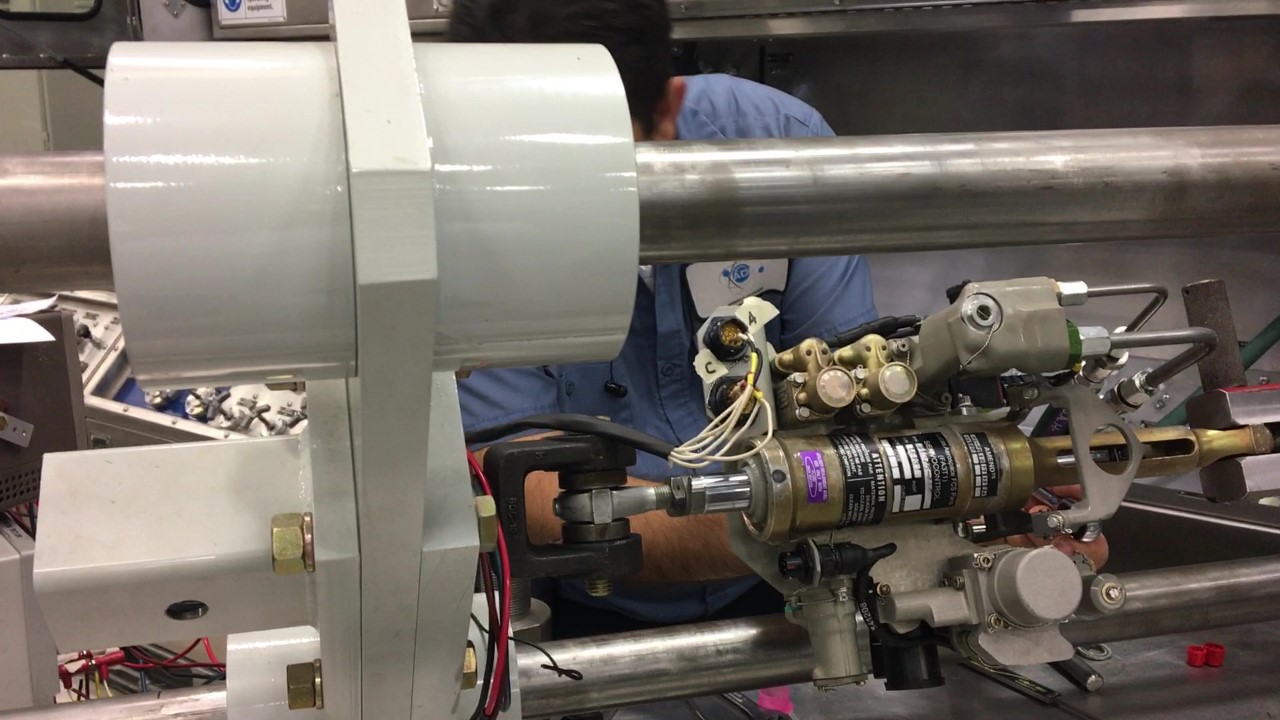

Actuator Assembly

Hydraulic actuator system

Actuator System

Complete assembly

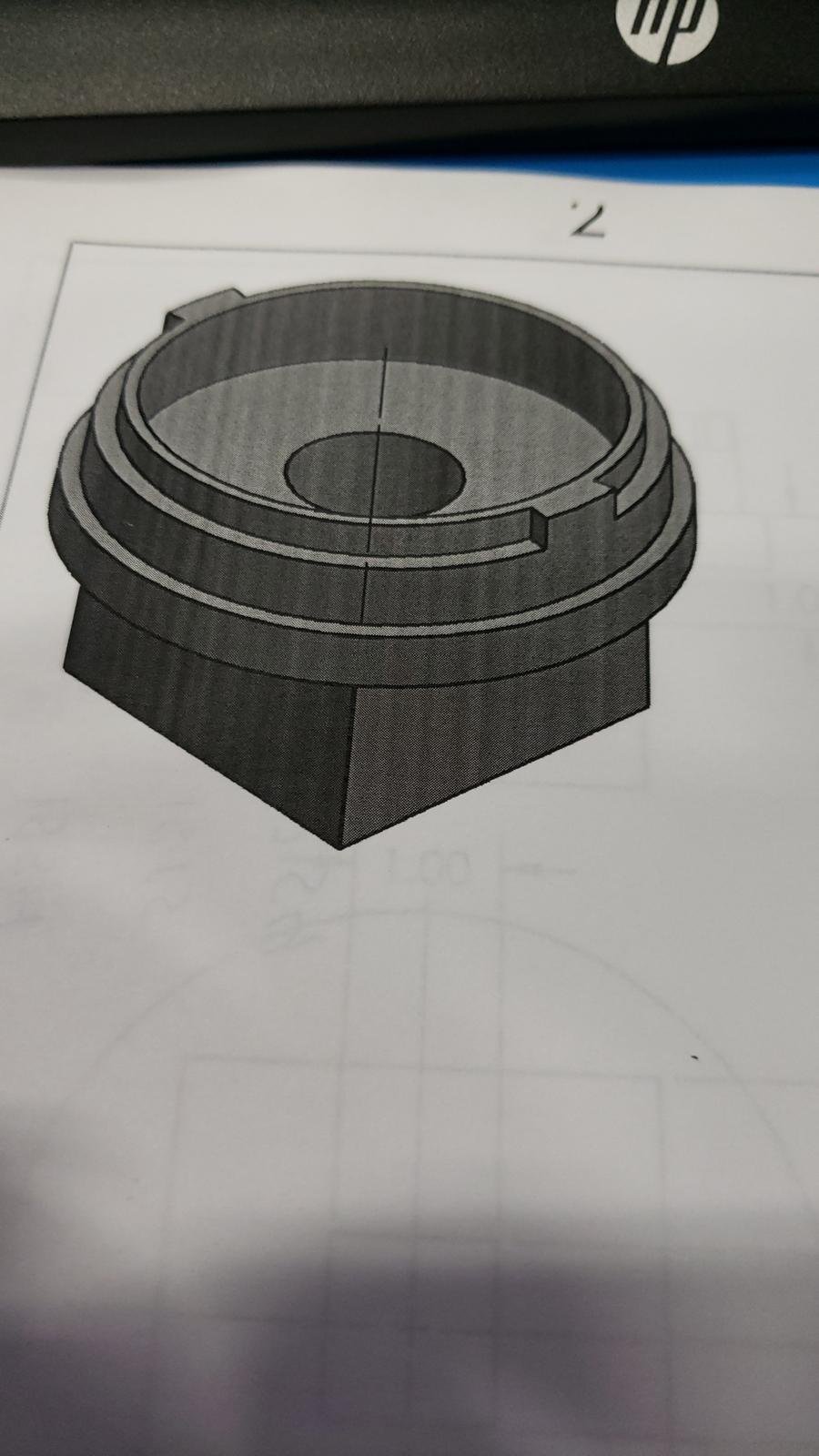

Custom Component

Machined aerospace part

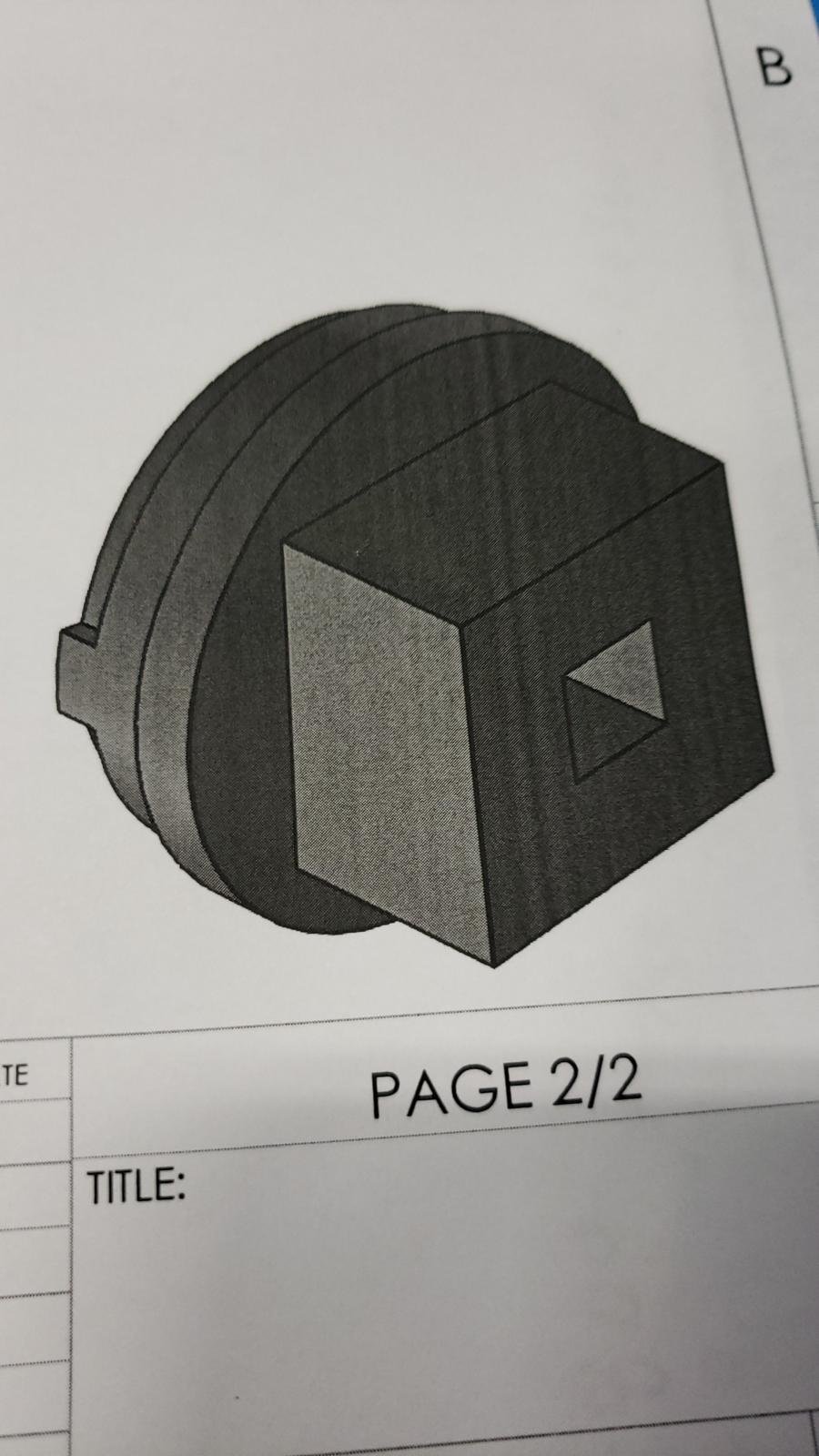

Part Detail

Reverse angle view

Live Installation

Machined component

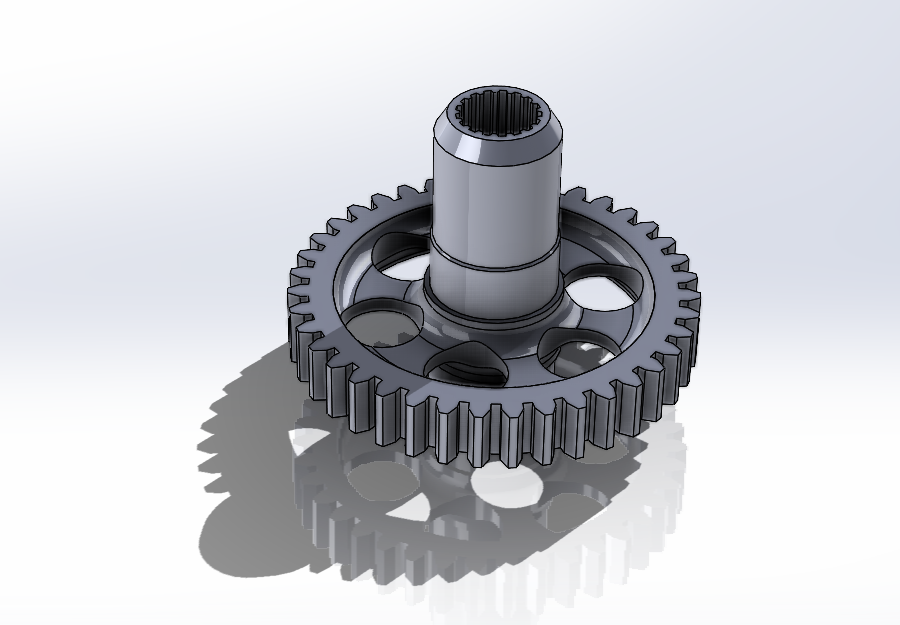

Gear Assembly

Precision machined gear

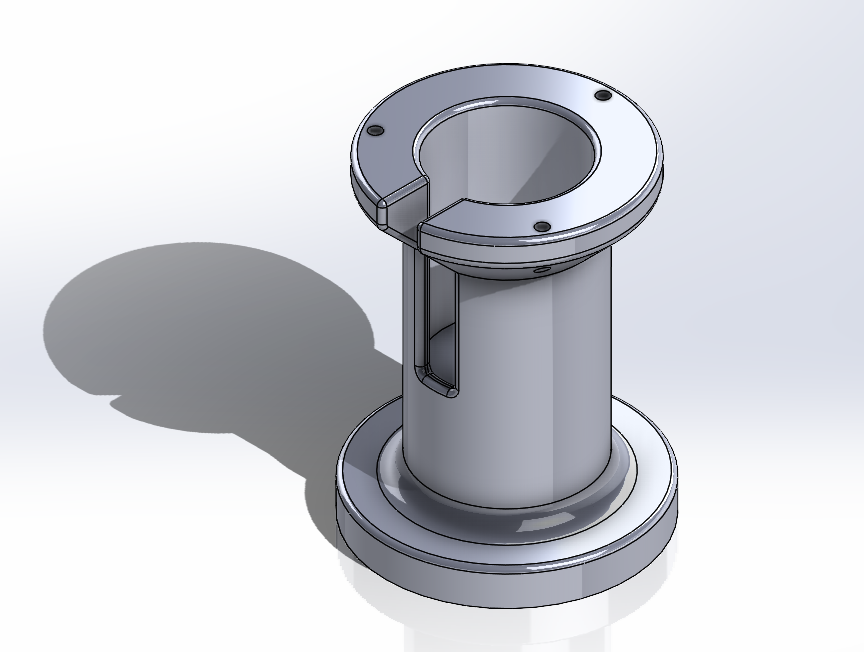

Tool Holder

Custom fixture

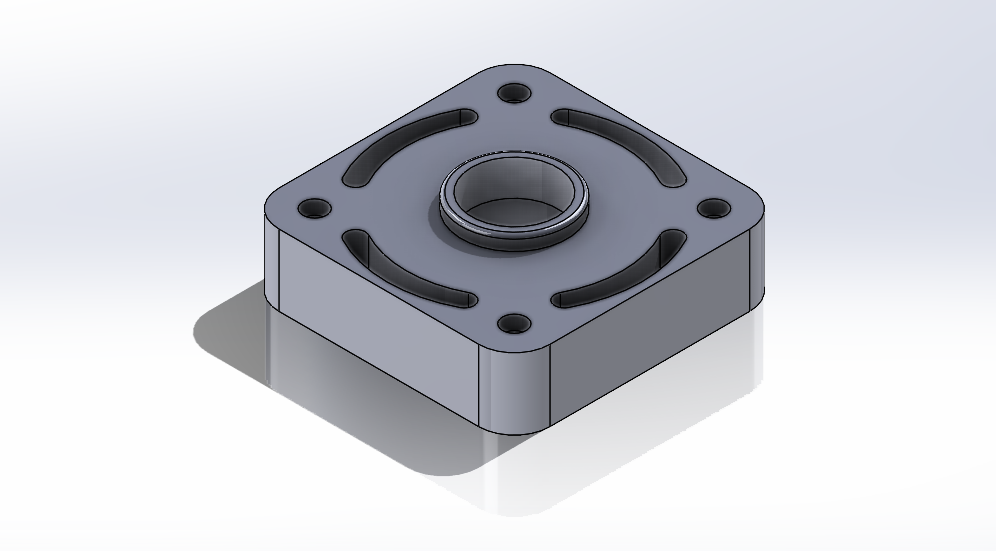

Holding Fixture

Assembly support

Ice Detector Holder

Sensor mount bracket

Sensor Cap

Protective cover

Sensor Holder

Mounting system

Precision Tools

Small component tooling

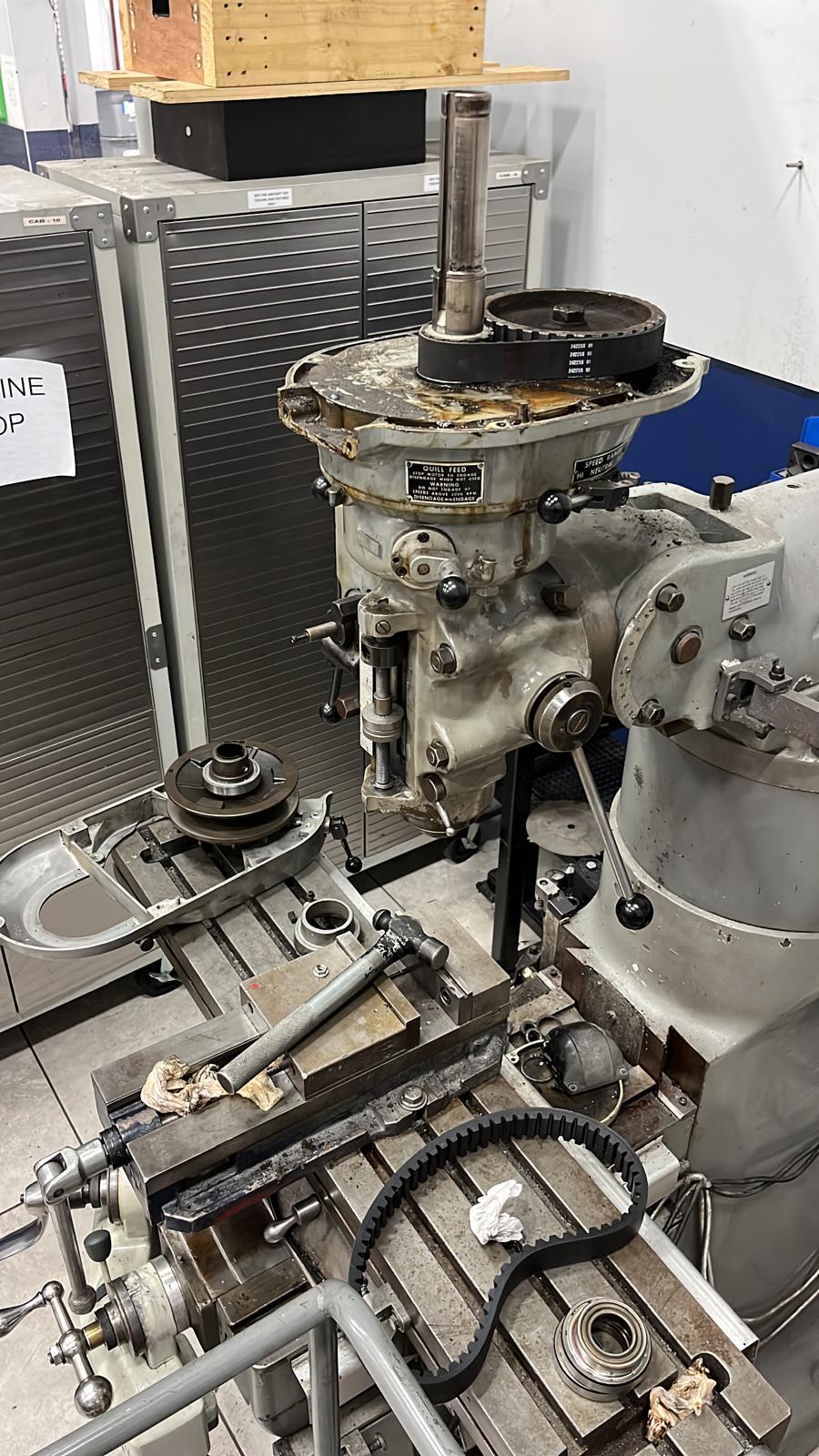

Milling Operations

Vertical mill work

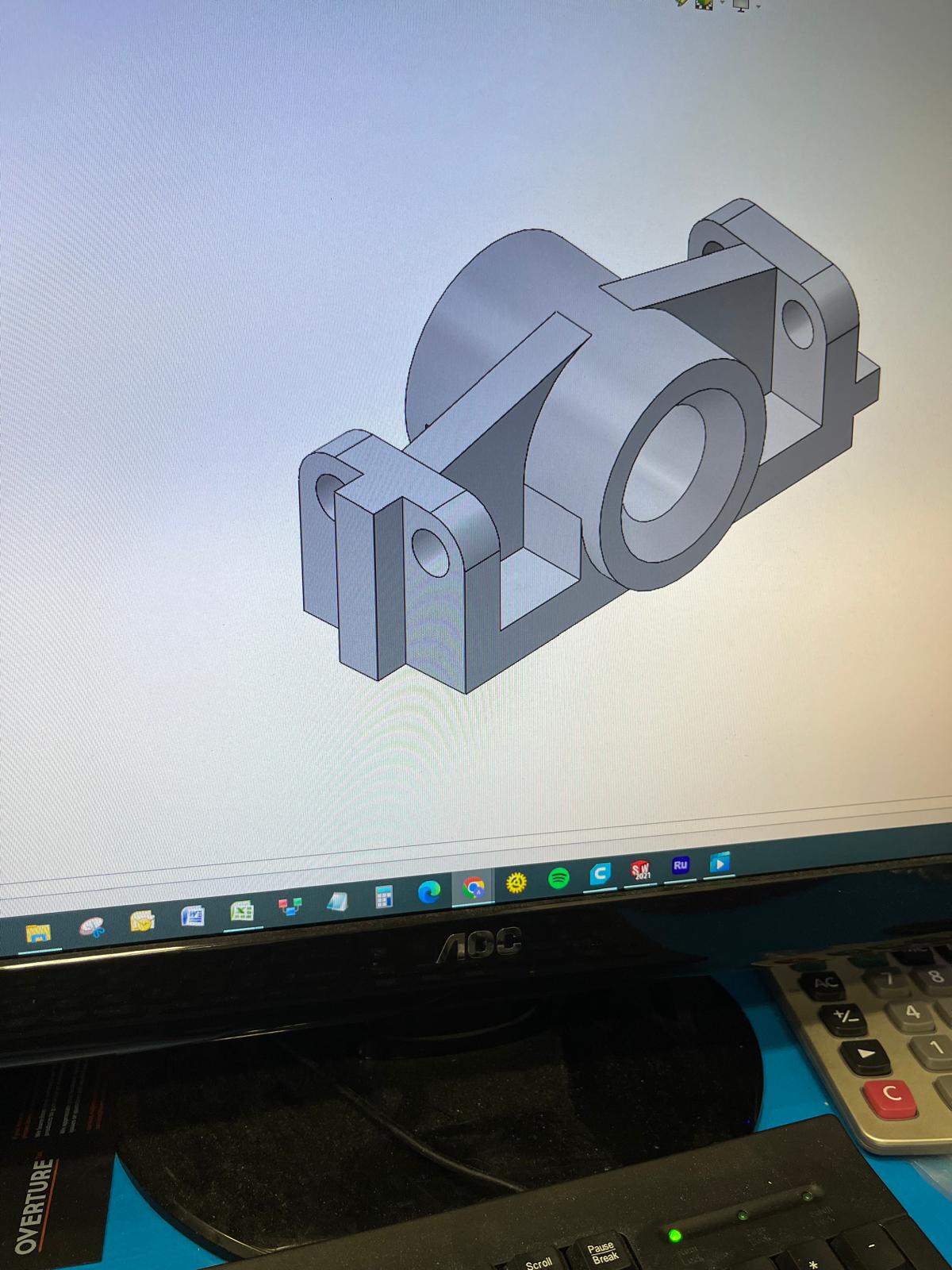

Engineering Space

CAD workstation

Lathe Operations

Lathe workstation

Skills & Tools Applied

SolidWorks

3D modeling & assemblies

ASME Y14.5

GD&T standards

3D Printing

Additive manufacturing

CNC Machining

Turning & milling

Quality Control

FAA compliance

Technical Drawing

Manufacturing docs

My Journey

Explore my career progression in aerospace engineering

Crew Tool

Precision tooling for aerospace manufacturing

September 2024 – September 2025

Airgroup Dynamics Inc.

Custom aerospace tooling and FAA compliance

May 2021 – September 2024

Florida Space Institute

Research and development in aerospace systems

January 2021 – May 2021