Crew Tool

Design Engineer

About Crew Tool

Crew Tool is a precision tooling startup specializing in aerospace manufacturing support. The company develops custom tools for sealant application and removal, designed to meet strict aerospace industry standards. Working at Crew Tool meant operating in a highly regulated environment where precision, quality control, and compliance were paramount to every design decision.

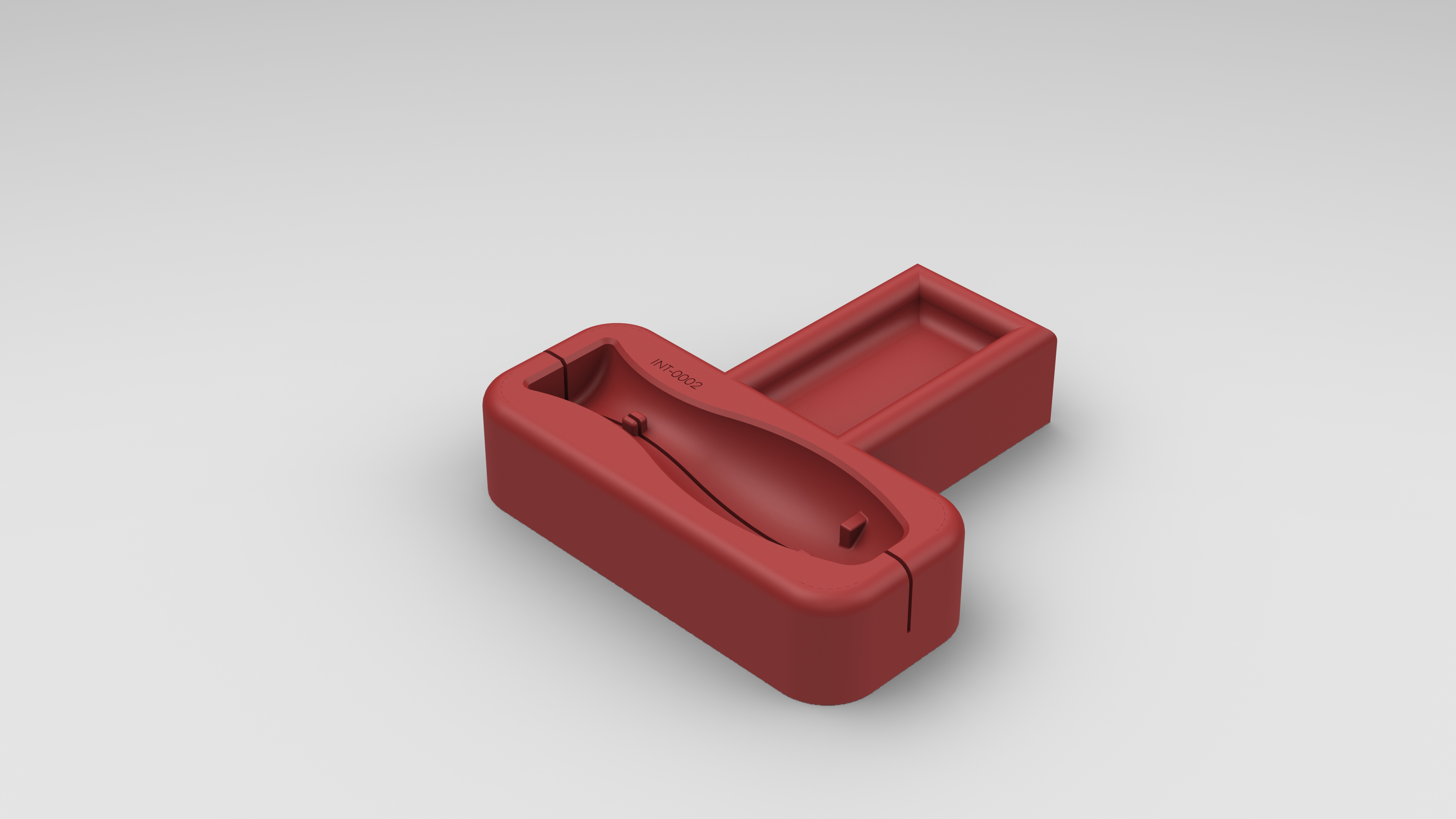

Modular Scraper Handle System

Designed a versatile handle system for interchangeable scraper heads used in aerospace sealant removal. The design featured a click-in-place mechanism that allowed operators to quickly swap between different scraper types without needing multiple complete tools.

- Created CAD models following ASME Y14.5 standards for dimensional accuracy

- Developed interlocking geometry to ensure secure attachment under operational loads

- Designed for ergonomic comfort during extended use on the shop floor

- Compatible with multiple scraper blade configurations for different applications

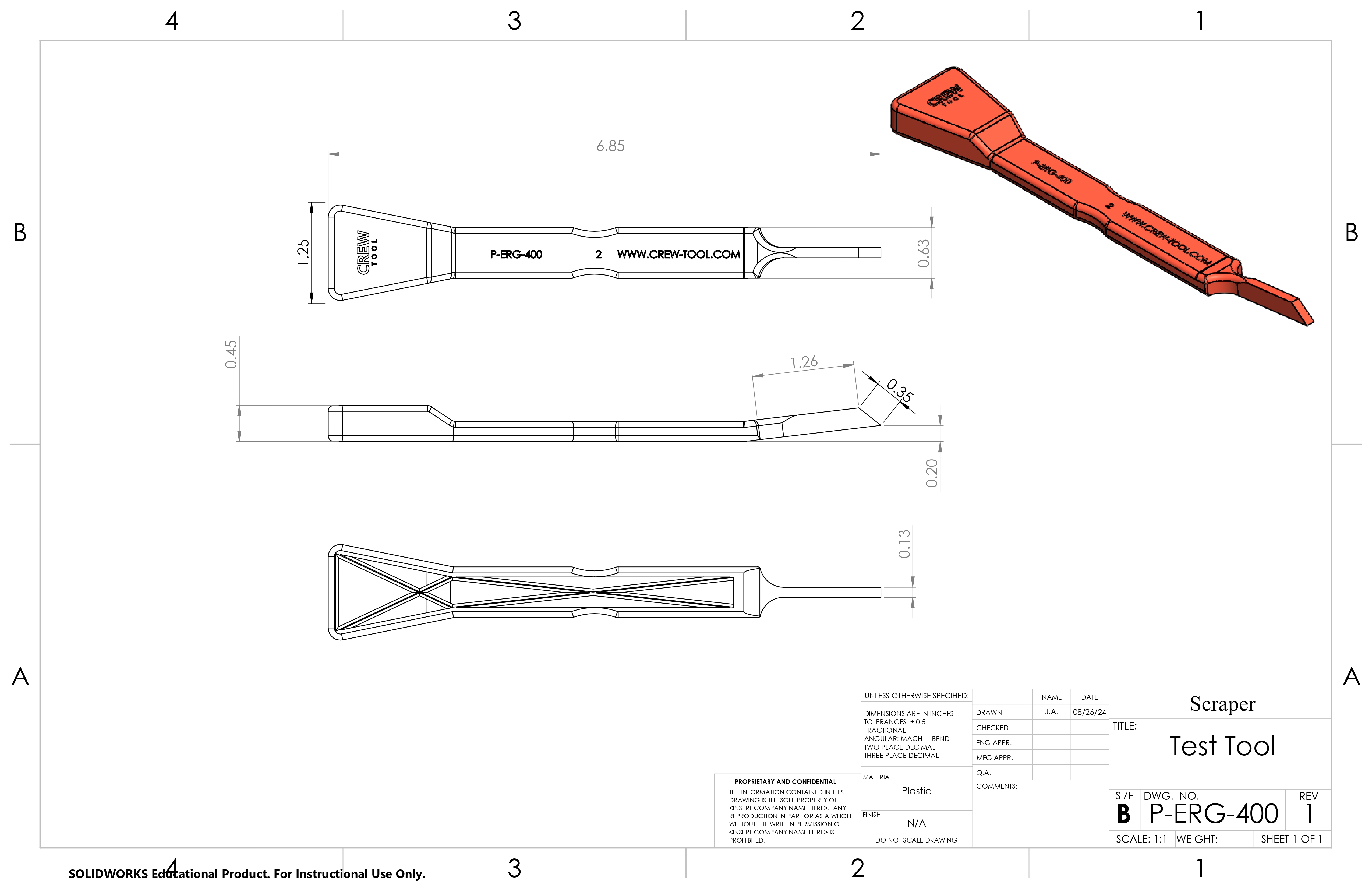

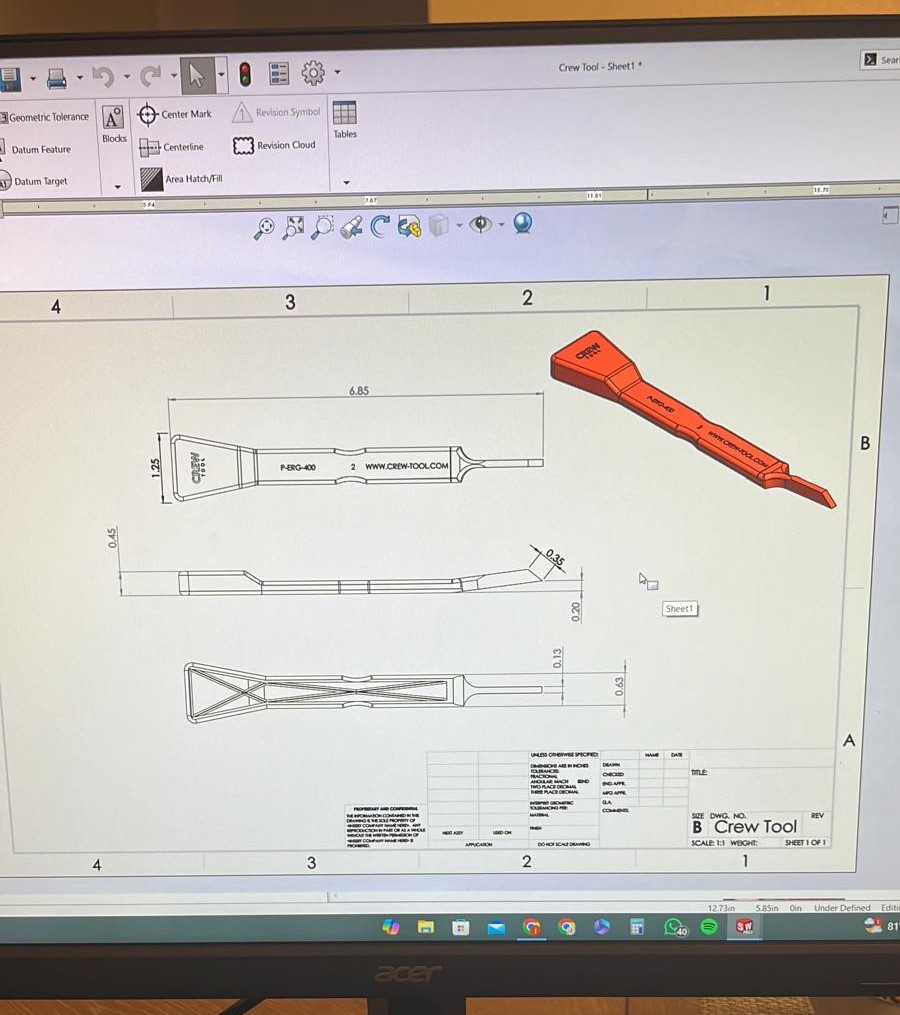

Design Assessment & Reverse Engineering

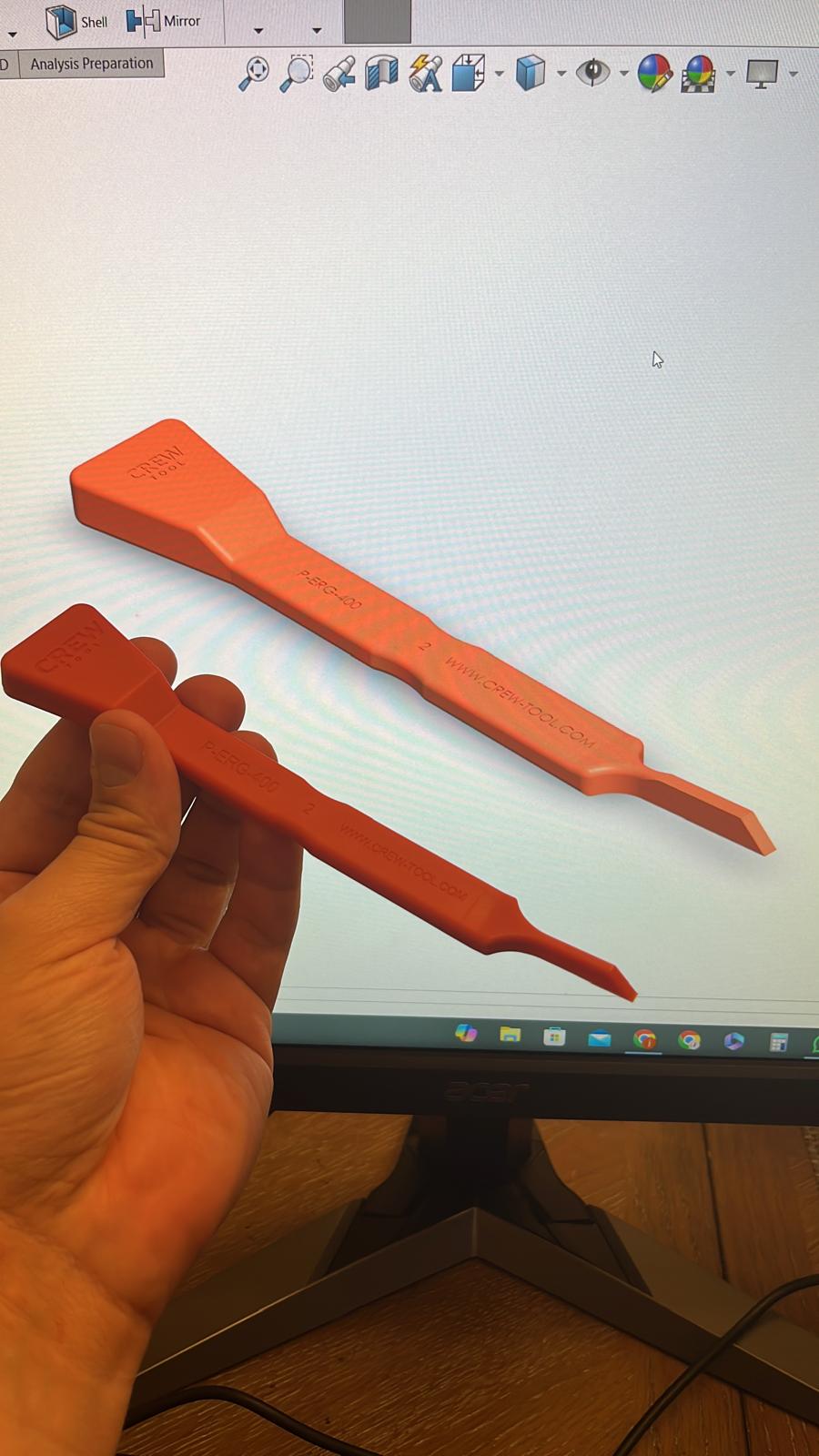

As part of the hiring process, I completed a practical design assessment that demonstrated core mechanical engineering skills. Given a physical scraper tool, I reverse-engineered it using precision measurement tools, then created a complete CAD model and manufacturing-ready technical drawing.

- Measured complex geometry using calipers to capture accurate dimensions

- Modeled the part in SolidWorks based on physical measurements

- Generated a complete manufacturing drawing with proper tolerances and title block

- Applied ASME Y14.5 standards for dimensional and geometric tolerancing

- Demonstrated ability to translate physical parts into producible documentation

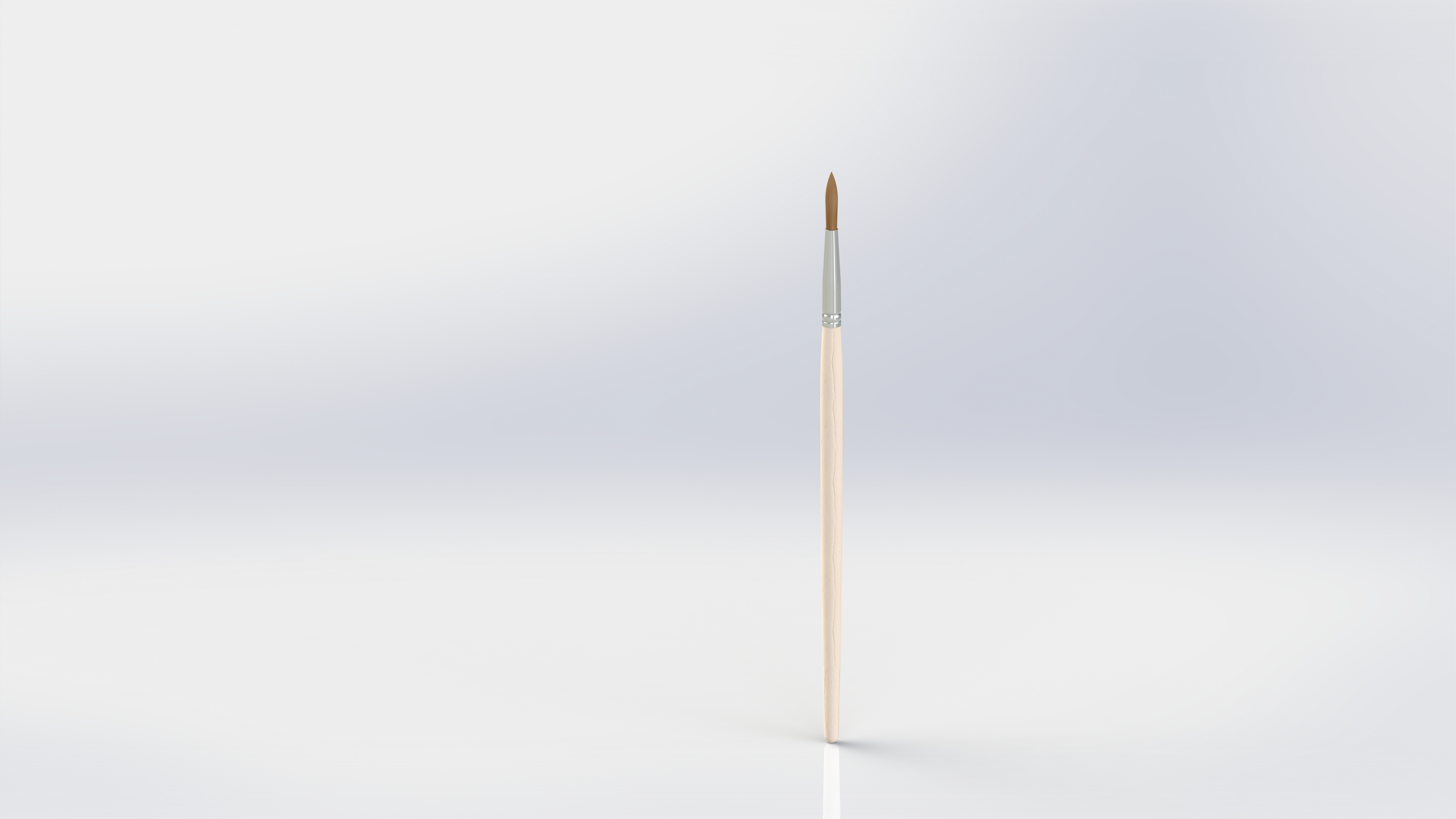

Precision Application Brushes

Modeled custom brushes for controlled sealant application in aerospace assembly environments. These tools were designed to meet Spirit AeroSystems specifications, ensuring consistent material application while maintaining operator control.

- Generated detailed 3D models for manufacturing and documentation

- Ensured designs met aerospace-grade material and tolerance requirements

- Coordinated with manufacturing to verify producibility

- Maintained compliance with industry quality standards

Technical Documentation & Drawings

Produced detailed technical drawings following ASME Y14.5 standards for aerospace tooling fabrication. These drawings served as the primary communication between design intent and manufacturing execution, ensuring precise dimensions and tolerances were maintained throughout production.

- Generated manufacturing drawings with complete dimensional specifications

- Applied geometric dimensioning and tolerancing (GD&T) principles

- Created assembly documentation showing part relationships and installation procedures

- Maintained drawing revision control and change documentation

From Design to Reality

The culmination of CAD modeling, technical documentation, and quality verification resulted in production-ready tools used on aerospace manufacturing floors. These custom scrapers demonstrate the full cycle from concept through fabrication, ensuring designs were not only functional but practical for daily operator use.

- Validated designs through physical prototypes and operator feedback

- Ensured manufacturability while maintaining aerospace quality standards

- Delivered tools that improved efficiency and consistency in sealant operations

- Balanced ergonomic requirements with functional performance demands

Skills & Tools Applied

SolidWorks

3D modeling & assemblies

ASME Y14.5

GD&T standards

FT-IR Testing

Material analysis

Quality Control

Inspection & verification

Aerospace Standards

Spirit AeroSystems compliance

Technical Drawing

Manufacturing documentation

My Journey

Explore my career progression in aerospace engineering

Crew Tool

Precision tooling for aerospace manufacturing

September 2024 – September 2025

Airgroup Dynamics Inc.

Custom aerospace tooling and FAA compliance

May 2021 – September 2024

Florida Space Institute

Research and development in aerospace systems

January 2021 – May 2021